AFC Industrial

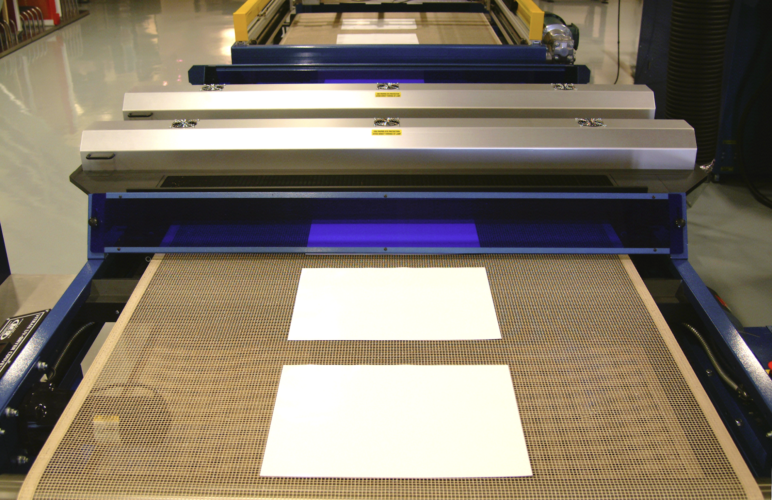

AFC manufactures a variety of PTFE and silicone-coated lightweight conveyor belting. These are commonly referred to as process belts, as some sort of change is imparted on the product when conveyed through a heat zone. This includes curing, cooking, and sealing, among other aggressive processes. PTFE-coated fiberglass is the ideal option for high temperature applications (up to 550°F or 287°C) that require consistent, clean release. Examples include:

- Press Belts for Tortilla and Pizza

- Contact Grilling Belts for Chicken and Other Meats

- Drying/Curing Belts for Can Manufacturing and Screen Printing

- Side Sealing Belts for Paper Packaging

- And Many More

Our belting comes in a variety of proprietary coating formulas, and can be found under the trade names DuraFab®, DuraFlow®, DuraSil®, and DuraLam®. With a variety of splices, edging & tracking mechanisms, and installation accessories, AFC can provide you with a solution suited for your specific application.

DuraFab® Industrial Fabrics

DuraFab® Industrial Fabrics are the general workhorse of AFC’s product line. The 20 series fabric is engineered to serve a broad range of industrial and……more

DuraFab® Mechanical Fabrics

DuraFab® Mechanical Fabrics feature a more textured surface than DuraFab®’s 20 Series Industrial Fabrics. The 22 series of fabric has been engineered to be……more

DuraFab® Food Grade Black Fabrics

DuraFab® Food Grade Black Fabrics have been manufactured to combine our DuraFab® Industrial Fabrics with a black finish commonly seen in the food processing industry……more

DuraFab® Premium Fabrics

DuraFab® Premium Fabrics are made for the most demanding applications, and utilize multiple coatings of a premium top coat to ensure maximum performance. This leads……more

DuraFab® Tear Resistant Fabrics

DuraFab® Tear Resistant Fabrics are specially manufactured to increase overall flexibility and tear resistance, making them extremely durable in any high-speed application. The fabric is……more

DuraFab® Anti-Static Fabrics

DuraFab® Anti-Static Fabrics are formulated to dissipate surface static build-up during any processes it is used in. The fabric is coupled with a premium top……more

DuraFab® Ultimate Fabrics

DuraFab® Ultimate Fabrics with a premium top coat offer the best value for abrasive applications and have been engineered to possess a pinhole and crack-free……more

DurEtech™ Hybrid Composite Fabrics

AFC’s DurEtech™ Hybrid Composites are revolutionary composite alloys that exhibit unrivaled performance in any high speed or abrasive application. The 75 series is combined with……more

DuraFab® Kevlar Fabrics

DuraFab® Kevlar® Fabrics are AFC’s best option for any heavy duty application where extreme strength, high loading, and long wear life is required. The Kevlar®……more

DuraSil® Silicone Fabrics

DuraSil® Silicone Fabrics are our most conformable, flexible, and wear resistant products. They are coated on one or both sides of the fabric with silicone……more

DuraFlow® Porous Fabrics

DuraFlow® Porous Fabrics are specially formulated to be breathable and maintain the non-stick properties offered by PTFE. The pores in the fabric allow products to……more

DuraFlow® Mesh Fabrics

DuraFlow® Mesh Fabrics are known for their exceptional performance in a wide variety of applications. Our proprietary coating formula has created a mesh that is……more

DuraFlow® Kevlar Mesh

DuraFlow® Kevlar® Mesh Fabrics are AFC’s best option for any heavy duty application where extreme strength, high loading, and long wear life are required. The……more

DuraLam® High-Performance Fabrics

DuraLam® High-Performance Fabrics are a gold laminate with PTFE coating that are excellent for the most demanding applications. This fabric is resistant to oils, grease……more

DuraFab® HD Elite Fabrics

NEW PRODUCT LINE: AFC’s most dynamic product line to date, the HD (Heavy Duty) Elite series was engineered for superior heat transfer while resisting abrasion……more

DuraFlow® Hydro Mesh

AFC’s DuraFlow® Hydro Mesh is the ideal material for applications that are exposed to significant moisture, grease, and oil levels. This thermoplastic mesh possesses high……more

Choosing the Right Belt for Your Application

Our Belt Design Guide demonstrates the steps required when choosing the right belt for your production line.

- Select Material Style (see Fabrics)

- Determine Belt Dimensions

- Width (edge to edge)

- Net Endless Length (continuous [closed] belt length)

- If existing belt is in good condition: lay belt on the floor and measure from one end of the belt to the other end.

- If existing belt is badly deteriorated: center the take-up pulley and measure the path of the belt through the dryer using a tape.

- Edge Reinforcements

- Splices/Seam Type

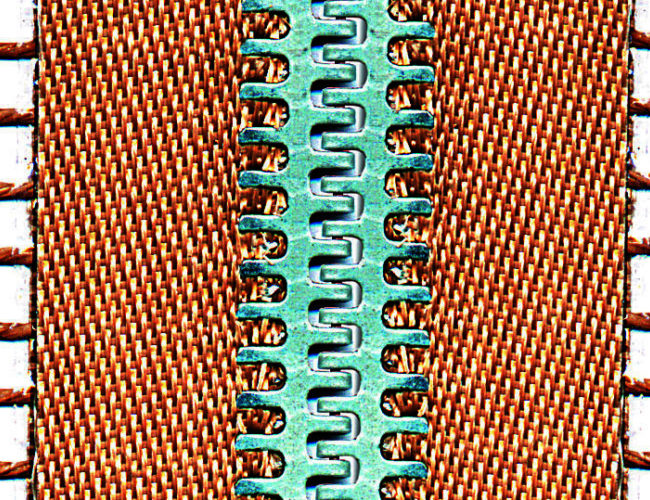

- Splice Options (can choose more than one)

- Flap over and/or under the splice (Mechanical Splice)

- Molding over and/or under splice (Butt or Overlap Splice)

- Stitched Splice

- Stitched Flap

- Custom/none

- Guiding and Tracking

Sample Belt Design:

Material 27-48, W36″ X L240″, 1″ Sewn and Sealed- Fiberglass, Galvanized Alligator, Flap Over Splice, No Guides

Please Note: Fabric and Belting over 80″ width and Mesh Belting over 89″ width might have extended lead time.

Belting Considerations

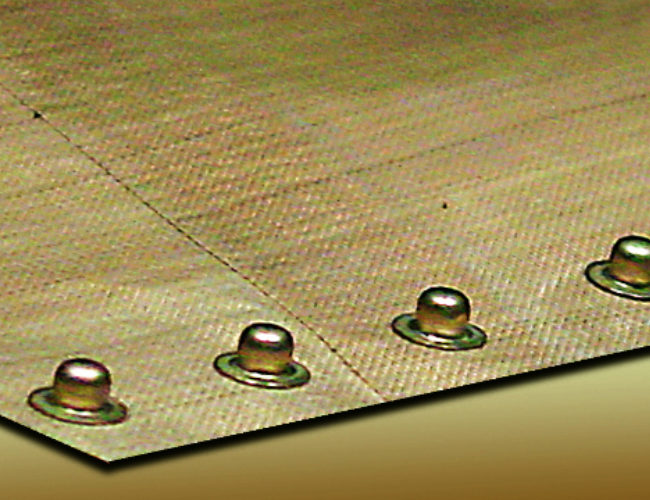

Edging, Guiding & Tracking

All of AFC’s belting have various edging and tracking options to chose from. Both edging and tracking can be placed on one or both sides……more

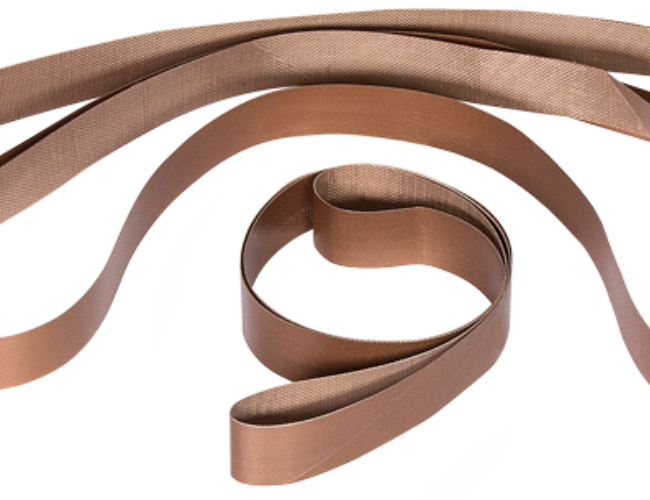

2-Ply Belts

Two-Ply Belts, commonly know as Band Sealer Belts, are small belts that are manufactured by laminating two layers of PTFE fabric together. Using a staggered……more