Custom Parts

A-L-M stocks a complete line of materials in sheet and rollstock form. We can machine or hand fabricate low volume, short-run, and prototype cut parts. Our custom parts fabrication product line includes matting, seals, UHMW parts, paddle conveyor paddles, bumpers, dampeners, flange gaskets, skirtboard, shims, boots, liners, bearing pads, and spacers just to name a few.

We have long-standing relationships with our suppliers and our purchasing department works hard to ensure customers have a broad range of quality materials available to them.

Don’t see a certain material? Please send your specification and we will find it…

Our Suppliers

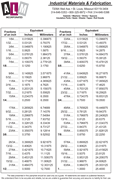

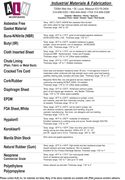

- Aluminized Fiberglass – Flexible, non-flammable cloth that is resistant to most chemicals; used as thermal seal, barrier, and over irregular surfaces

- Asbestos Free Gasket Material – Temp.: 400°C (750°F) 450PSI Non-asbestos fibre bonded with nitrile rubber for high chemical stability and heat resistance. Thickness range: 1/64” to 1/8”

- Beater Add – a mixture of water, latex, fibers, fillers, and chemicals

- Buna-N /Nitrile (NBR) – Temp. range: -20°F to +170°F; good oil and leaded gasoline resistance, ASTM D2000 SAE J 200. Thickness range: 1/32” to 1”

- Butyl (IIR) – Temp. range: -40°F to +225°F; excellent resistance to gases, sunlight, ozone, and alcohol. Non oil-resistant, ASTM D2000 SAE J 200. Thickness range: 1/16” to 1/4”

- Cellulose Fiber – Made with plant fiber; good sealing of oil and fuel; insulating properties

- Ceramic Fiber – Use in high-temperature, low-pressure applications

- Chute Lining (Plain, Fabric, or Metal Back) – Temp. range: -20°F to +170°F; good abrasion resistance. Thickness range: 1/8” to 1” (Rubber-Urethane)

- Closed Cell Sponge – Temp. range: -20°F to +160°F; intermittent ASTM D1056- 68; gasketing, sealing, cushioning, stripping, vibration dampening, shock absorption, and packaging; rubber is soft, flexible, and highly durable. Oil-resistant weather-strip; Thickness range: 1/16” to 1”

- Cloth Inserted Sheet – Temp. range: -20°F to +170°F; non oil-resistant for static and low-pressure use; Compound-SBR. Reinforcement: Cotton and Polyester. Thickness range: 1/16” to 1/4” (Other styles available)

- Cork/Rubber – Neoprene Nitrile filler, low-cost general service material for cushioning and sealing ASTM-P.2265A. High compressibility and flexibility; oil resistant. Thickness range: 1/16” to 1/4” (Other styles available)

- Cracked Tire Cord – Good wear and abrasion resistance sheet, 85 duro. A homogenous mixture of masticated rubber reinforced with high strength rayon cords; good load-bearing qualities; bearing pads, bumpers, and wear pads. Thickness range: 1/8” to 1/2”

- Diaphragm Sheet – Temp. range: -20°F to +220°F; nitrile/nylon premium grade; good oil and regular gas resistance; very flexible. Thickness range: 1/32” to 1/8” (Other styles available)

- EPDM – Temp. range: -40°F to +220°F; resistance to sunlight, ozone, and oxidants; used with farm chemicals including Lasso. Non oil-resistant. Thickness range: 1/8” to 1/4”

- FDA Sheet, White – Temp. range: -25°F to +220°F; can be used in greasy, oily, and abrasive conditions, especially food handling, drug and cosmetic manufacturing. Non-toxic, non-allergenic, and non-marking. Thickness range: 1/16” to 1/4”

- Felt – Wool fibers; soft and compliant with a high level of resiliency; can absorb and hold liquids; won’t unravel or fray; use for noise-deadening or insulation

- Fiberglass Reinforced Silicone – Flexible, resilient, nonporous sheet material; resistant to deterioration by weathering and oils

- Fish Paper – lightweight, durable; good forming and bending qualities; use in electrical applications, coil insulations, and insulation washers

- Flexible Graphite – Temp. range (oxidizing atmosphere): -400°F to 750°F; can withstand up to 5,400°F as long as oxygen is not present; manufactured from mineral graphite and contains carbon content between 95-99%

- HDPE – High-Density Polyethylene; properties of minimal moisture absorption, resistance to chemicals, and good strength

- Hypalon® – Temp. range: -40°F to +250°F; moderate oil resistance. Excellent resistance to oxidizing acids and ozone. Tensile strength 2250 PSI. Thickness range: 1/16” to 1/4”

- Kapton® – Polyimide film provides excellent electrical insulation, abrasion resistance, high dielectric strength, and conformability

- Koroklear® – Temp. range: -40°F to +150°F; Clear vinyl strip used in doors, energy-saving, and noise reduction. Widths of 6”, 8”, 12”, 16” and 48”, regular and U.S.D.A. Thickness range: .040” to .160”

- Linatex® – A 95% natural rubber that exhibits outstanding resilience, strength, and resistance to cutting, tearing, and abrasion

- Manila Shim Stock – Shim stock and gasket applications

- Masticated Rubber – Firm compression with high hardness, tensile strength, tear strength, and elongation properties

- Mylar – General-purpose polyester film that is resistant to chemicals, extreme temperatures, and moisture; great electric insulator; abrasion-proof

- Natural Rubber (Pure Gum) – Temp. range: -20°F to +140°F; high tensile and tear-resistant properties; superb abrasion and wear-resistance. Non oil-resistant. Excellent for Dry Product Discharge Sleeves. Thickness range: 1/32” to 1”

- Natural Rubber Sponge – Temp. range: -40°F to +175°F; 200 intermittent. ASTM D1056-73. Cushioning, gaskets, vibrating dampening, expansion joints. Thickness range: 1/8” to 1”

- Neoprene (Commercial Grade) – Temp. range: -40°F to +170°F; our most popular sheet. Good oil resistance and aging properties. Thickness range: 1/32” to 1” and up to 72” wide

- NSF-61 CERTIFIED EPDM – Use in potable water applications

- Nylon – Silky, thermoplastic material; demonstrates toughness, resilience, hardness, and high melting points

- Open Cell Sponge – Rubber is permeated with open, interconnected pockets that allow for the passage of air, water, and other media; maintains its shape very well when compressed; good resistance to oils and other chemicals

- Polyethylene/ EVA – Commonly used for shock absorption, gasketing, floatation, cushioning. Low-cost multipurpose material. Thickness range: 1/8” to 2-1/2”

- Polyethylene/ Foam – Temp. range: -100°F to +180°F; excellent chemical and weather resistance; soft surface texture with great compression recovery; superior insulating and cushioning combined with lightweight; unusual strength. Thickness range: 1/8” to 4”

- Polyethylene/ Polypropylene – Stress relieved–as extruded. Thickness range: 1/16” to 2”

- Polyurethane Foam – Temp. range: -30°F to +250°F; low-cost material for cushioning, vibration dampening, dust and insect sealing around doors, windows, etc. Thickness range: 1/8” to 12”

- Poron® – High-density polyurethane foam; durable, shock-absorbing, and impact protection; use for sealing, insulating, and cushioning

- PTFE (Polytetrafluoroethylene) – Synthetic fluoropolymer; commonly known as Teflon®; low-friction properties, high melting temperature, high corrosion-resistance, high resilience; highly resistant to chemicals, solvents, caustics, and acids

- PVC (Polyvinyl-Chloride) – Temp. range: +40°F to +140°F; for petroleum and corrosive service. Excellent oil resistance. Thickness range: 1/16” to 1/8”

- Red Rubber (SBR) – Temp. range: -20°F to +170°F; general-purpose gasketing; non oil-resistant; good water and some chemical resistance. ASTM D-1330-66, Class II; Thickness range: 1/16” to 1/4”

- Reinforced Graphite – Excellent corrosion resistance, compressibility, and recovery; high temperature resistant, use for piping, valves, pumps, pressure vessels, heat exchangers, condensers, generators, compressed machine, exhaust pipes, or chillers

- Santoprene – Thermoplastic elastomer vulcanized rubber particles dispersed throughout a heat-formable plastic base; high resistance to compression set after repeated deflection; excellent at high temperatures and long periods of time; use for potable water, water treatment, and tight sealing; can be thermally welded

- Silicone – Temp. range: -60°F to +480°F; very stable at low and high temperatures; good ozone and UV resistance. Thickness range 1/32” to 1”

- Silicone Sponge – Temp. range: -100°F to +450°F; hi-temp resistance, lo-temp flexibility. Low moisture absorption; chemical resistance; non-corrosive. Bondable with R.T.V. Thickness range: 1/8” to 12”

- Skirtboard Rubber – Temp. range: -40°F to +170°F; good abrasion resistance. Thickness range: 1/8” to 1”

- Styrene-Butadiene Rubber (SBR) – Excellent impact and tensile strength; good resilience, abrasion resistance, and low-temperature flexibility; non-oil resistant

- Teflon® Mechanical GradeVirgin Glass Filled – Temp. range: -200°F to +500°F; excellent impermeability to most corrosive liquids, vapor, and gases, even at elevated temperatures. Plain or bondable. Thickness range: 1/32” to 2 1/2”

- Thermal Barrier – 3000°F melting point. Non-asbestos material; welding and burning operations; gasket applications. Thickness range: 0.030 and 0.060, 36” wide

- UHMW – Ultra High Molecular Weight polyethylene. Extremely high abrasive resistance; USDA and FDA accepted for food processing. Use caution on impact. Thickness range: 1/16” to 4”

- Urethane – Good aging and excellent abrasion, tear, and solvent resistance; resistant to Ozone, hydrocarbons, moderate chemicals, fats, oils, and greases

- Vegetable Fiber Sheet – Temp. 250°F; tough, pliable, and compressible; flange gaskets in sealing fluids or gases. Not recommended for acids. ASTM 1170-62T SAE J90. Thickness range: .010” to 1/8”

- Vinyl/Nitrile Closed Cell Ensolite® – Commonly used in floatation, shock absorption, gasketing, sound and thermal insulation. Thickness range: 1/8” to 2-1/4”

- Viton® – Temp. range: -10°F to +400°F; excellent heat and fluid resistance; gaskets, seals, and coated fabrics. Cellular-Thickness range: .010” to 1/2” Also available Viton on Nomex

- Vulcanized Fiber – Laminated plastic composed of only cellulose; contains no resins or bonding agents; extremely high internal bond strength; lightweight, tough, and resilient; oil-resistant; will not delaminate or separate, even in water.

Additional materials are available upon request. Many of the above materials are available with (PSA) pressure-sensitive adhesive.